At Telfid, we offer a wide range of machining services including CNC turning, milling, EDM cutting, with 3-, 4-, and 5-axis capabilities. We always prioritize quality, and thus continuously invest in our equipment to offer the latest technologies and to ensure that your product excellence is never compromised.

Relevant Capabilities

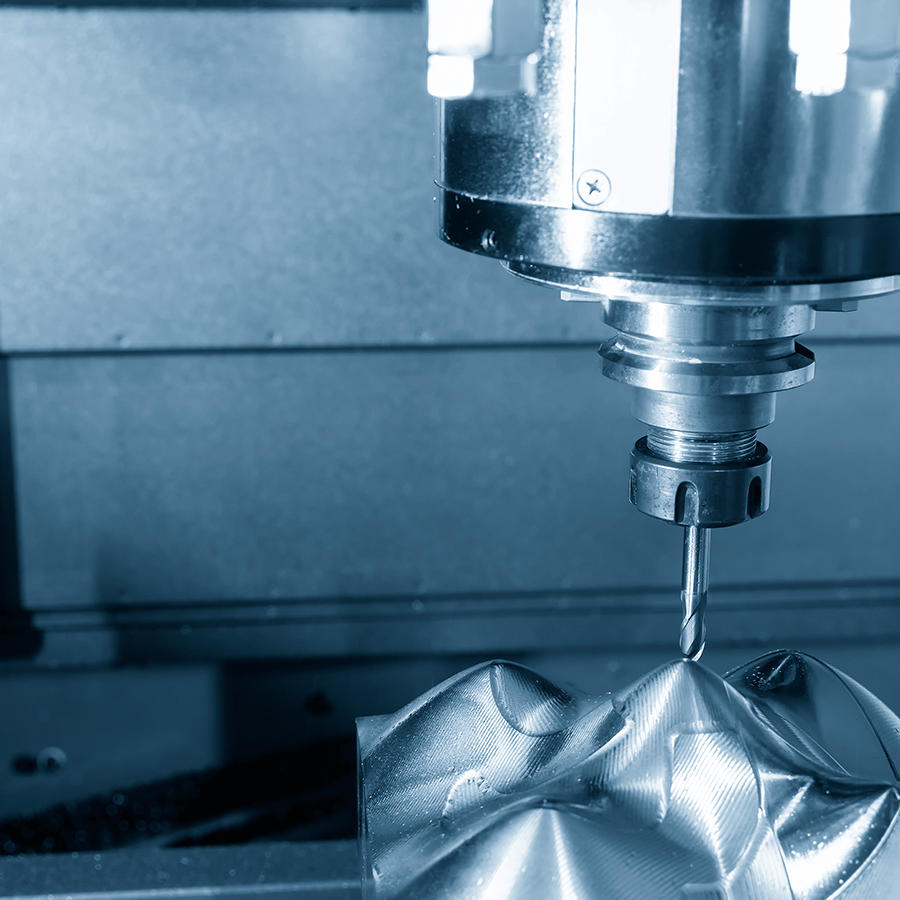

CNC Milling

CNC Milling is the process of cutting and drilling material by using a rotating cylindrical cutter and is extremely useful in producing items with complicated geometries, as is often the case in outdoor sporting goods such as archery and gun accessories.In addition to skillful programmers, we have advanced 3-, 4-, and 5-axis CNC mill-turn centers that produce almost any shape, holding tolerances at 0.001mm for most metals and alloys.

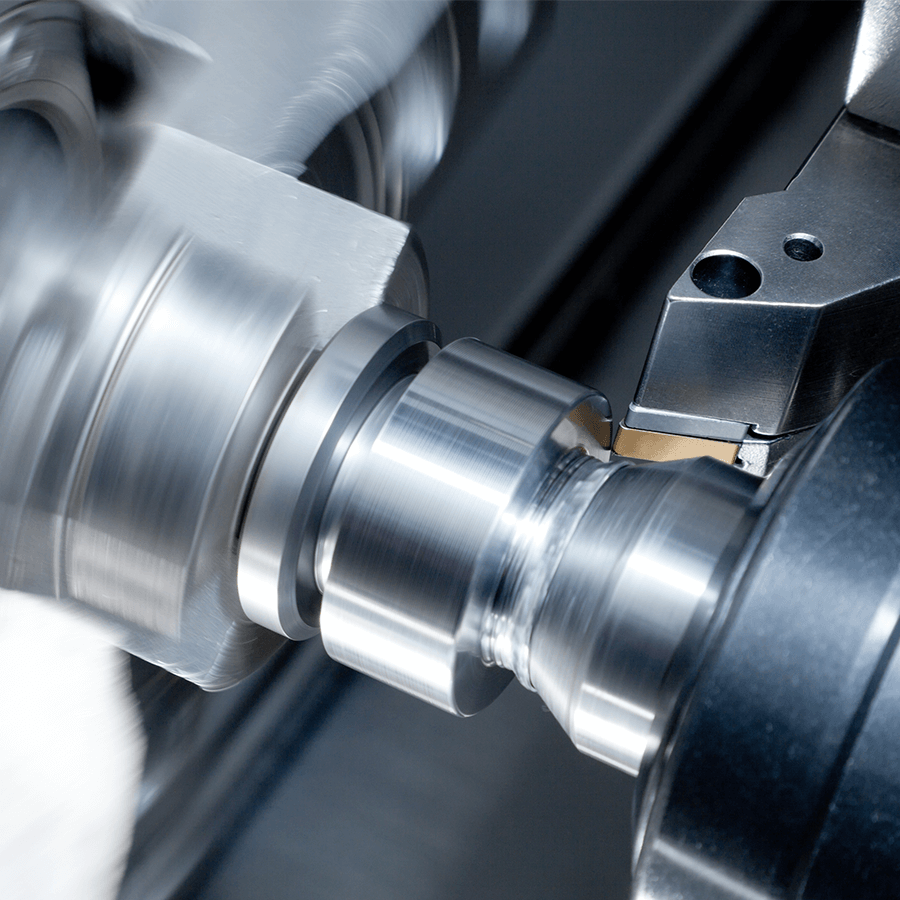

CNC Turning

Turning is an effective and efficient method to machine round/cylindrical items, such as choke tubes, bearings, arrows and points/broadheads. During turning, a workpiece is held in place while rotating, during which process a cutting tool moves in a straight line along the workpiece, making cuts and adding details. Our high-precision automatic lathes and is capable of producing parts with TIR of 0.002mm.

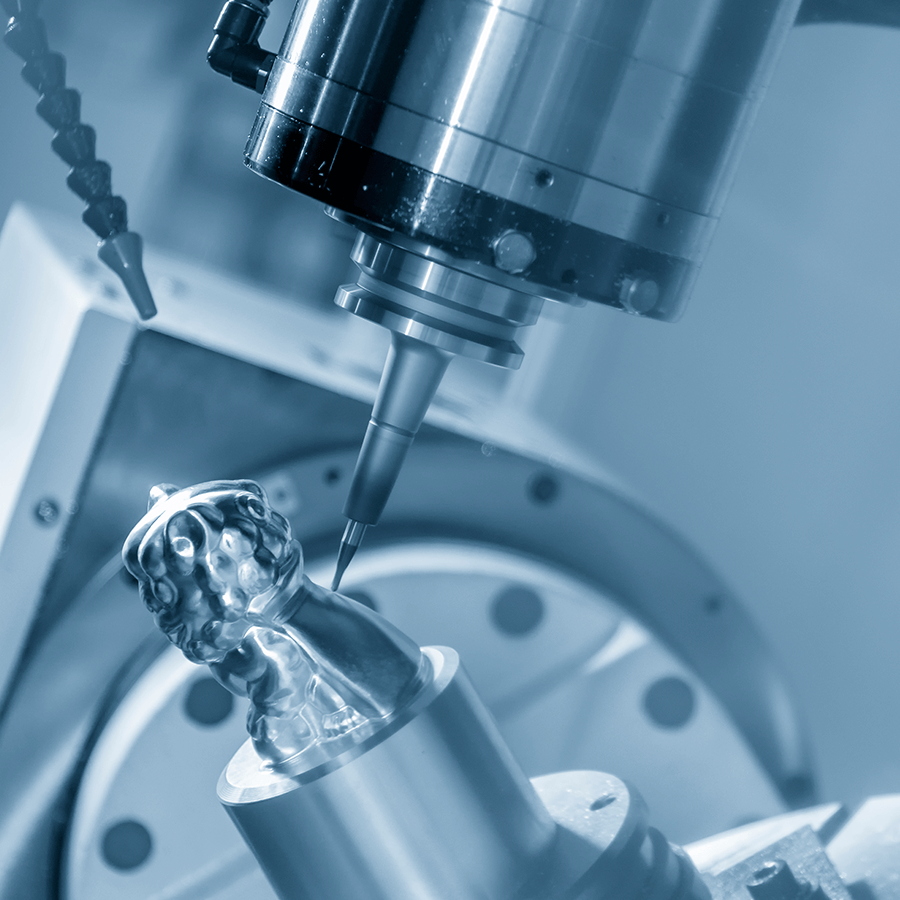

5-Axis Machining

When it comes to milling, cutting can be performed in multi-axis, with the most common variety being the 3-axis milling, which refers to cutting in x-y-z directions. As shapes get more complex, there is often the need to cut from the bottom of the workpiece, as well as rotating the workpiece around the x- and y-axis while cutting. This is where 4- and 5-axis come in handy. By incorporating rotation in both the x- and y-axis, 5-axis machines deliver the most complete milling process that will man than satisfy the machining requirements of the most complex sports equipment.